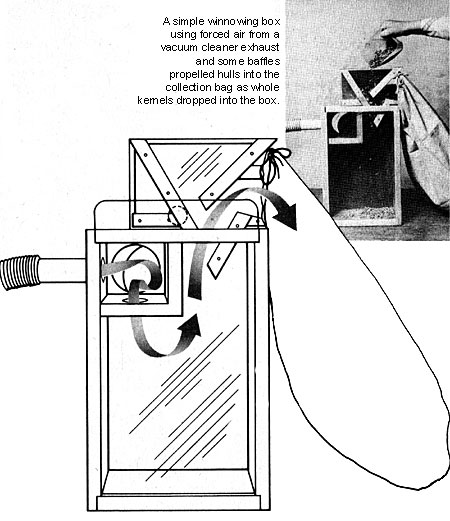

Winnowing Machine For Sunflower Seeds

The winnowing machine operates on the age-old principle of blowing the chaff away from the heavy grain with a controlled current of air.

The unit uses a household or shop-type vacuum cleaner for its air supply. A vacuum cleaner was used as a power source because it can supply a large volume of air over an extended period of time, and most homes and farms have a vacuum cleaner.

A cloth bag has been attached to the chaff chute to catch the chaff as it is separated from the seed. The bag allows the hulls to be collected and greatly reduces the amount of waste material normally blown into the air by conventional systems.

The unit has been constructed in such a way that the cloth bag and cleaner box can be placed inside the seed box, making a compact package for storage.

Tools Required

1. Table Saw

2. Drill Press

3. Band Saw

4. Saber SawProcedure (cleaner box)

I . Cut out the two sides of the cleaner box from 1/4-inch plywood.

2. Cut out the six interior pieces of the cleaner box from 3/4 x 3-1/2-inch select pine.

3. Assemble the cleaner box elements with glue and nails.

4. Cut four 1/4-inch square strips of pine four inches long.

5. Glue the strips around the end of the chaff chute.

6. Sand all surfaces and edges.

7. Finish with clear lacquer finish.Procedure (seed box)

1. Cut two pieces of pine /34" x 5 /12 x 15 inches for the sides.

2. Cut two pieces of pine 3/4 x 5-1/2 x inches for the top and bottom.

3. Plow a /14 x 1/4 groove for the front and back panels in all four pieces.

4. Rip the top board to 5 inches so that the front panel can slide into the grooves in the side boards.

5. Rabbet both ends of each 15-inch side piece to accept the top and bottom boards.

6. Drill a hole in the left side board 2-1/2 inches from the top. The size of the hole is determined by the vacuum cleaner hose fitting.

7. Cut a 3-1/4 x 4 inch hole in the top 1/2 inch from the right end. This hole will accept the cleaner box.

8. Cut two pieces of pine for the baffle.

9. Drill two 1-inch holes in the bottom of the baffle box.

10. Cut a piece of 1/4 x 8-1/2 x 14 inch plywood for the back panel.

11. Cut a 3-inch hole, centered 1-7/8 inches from the top and left sides of the plywood back.

12. Assemble the sides, baffles, top, bottom, and back panel with glue and nails.

13. Cut an 8-7/16 x 15-3/4-inch piece of Plexiglas for the front.

14. Cut a one-inch radius on the top corners of the front.and sand the edges.

15. Drill a one-inch thumb hole centered 7/8 inch from the top edge.

16. Cut a 3-1/2-inch disk of 1/4-inch plywood for the vent cover.

17. Drill a 3/16-inch hole 3/8 inch from the edge of the disk.

18. Mount the disk over the vent with a #10 x 1-inch screw.

19. Sand all surfaces and edges of the, box.

20. Finish with clear lacquer finish.Materials

Cleaner Box

2 -- 7-3/4 x 7-1/2 x 3/4" plywood (sides)

6 -- 3/4 x 3-1/2 x 24" for all members (baffles)

4 -- 1/4 x 1/4 x 4" pine (chute cleats)

22 -- 1" x 18 ga. headed nails

White vinyl glue

Clear lacquer finishSeed Box

2 -- 3/4' x 5-1/2 x 15" select pine (sides)

2 -- 3/4 x 5-1/2 x 8-1/2" select pine (top and bottom)

1 -- 3/4 x 3-1/2 x 4-1/2" select pine (baffle)

1 -- 3/4 x 4-1/2 x 4-1/2" select pine (baffle)

1 -- 1/4 x 8-1/2 x 14" plywood (back)

1 -- 1/4 x 3-1/2" dia. plywood (control valve)

1 -- 1/4' x 8-7/16 x 15-1/4" Plexiglas (front)

1 - #10 x 1" flat head screw

18 - 4d finish nails

White vinyl glue

Clear lacquer finish

1 -- 17 x 31" cloth laundry bag